The Magic of Creating Immortelle Essential Oil: A Step-by-Step Distillation Process

Immortelle essential oil, cherished for its healing properties, is obtained through a precise distillation process.

In this post, we uncover the secrets behind creating this precious oil, exploring each stage of the process that makes it almost alchemical.

1. Harvesting the Plant: Why is harvesting the plant the most important part for creating high-quality immortelle essential oil?

Before we begin the distillation process, we need to have an immortelle flower that is in full bloom, and such a flower is usually harvested in the hottest part of the day when the natural essential oils of immortelle are most concentrated.

The plant is harvested by hand, considering that distillation must be carried out within 24 hours to maximize the yield and quality of the oil.

2. Preparing the distillation boiler: How to properly prepare the container for the distillation process?

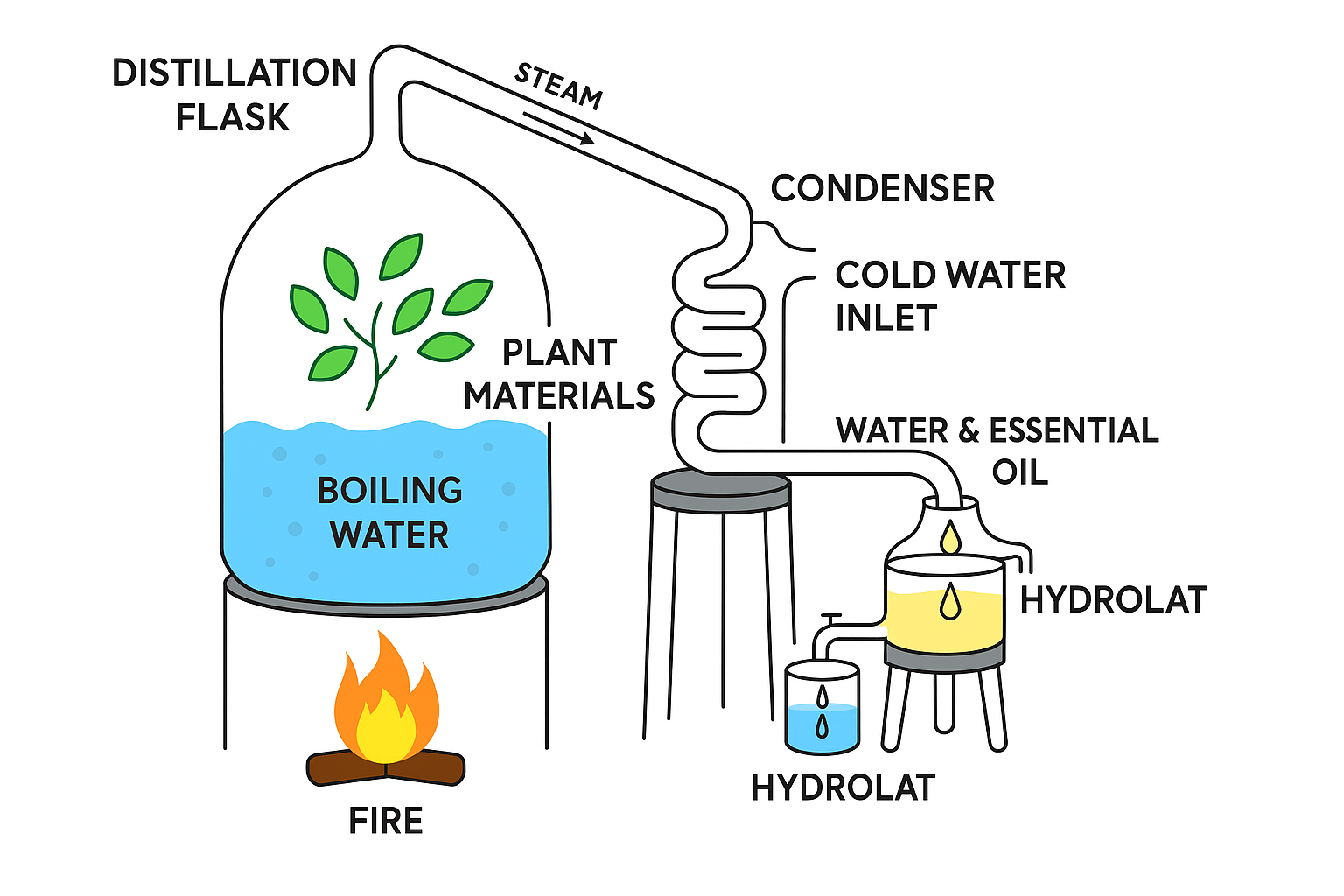

Distillation boilers must be precisely prepared. The immortelle is carefully placed on a perforated tray above the water level. This allows the steam to pass efficiently through the plant material without direct immersion.

3. The heating and extraction process: What happens inside the boiler?

When the water in the boiler is heated, the steam rises, passes through the plant, releasing and absorbing the essential oils from the plant material. This process requires monitoring the temperature to ensure that the plant components do not burn.

4. Condensation and oil separation: How does this process work?

When the oil-rich steam reaches the condenser, it cools and turns back into a liquid state. In a Florentine flask, the oil separates from the water phase because it is less dense than water and naturally floats to the surface.

5. Hydrosol – a valuable by-product: How is it used?

Immortelle hydrosol, which is collected during distillation, has numerous applications, from aromatherapy to cosmetic products. Its production is also an indicator of the quality of distillation, with the first 15 minutes of distillation being the highest quality part.

6. Distillation duration: How does the duration of the distillation process affect the quality of the oil?

The duration of distillation varies depending on the size of the boiler. For large commercial boilers, the process can take several hours, while smaller boilers require shorter periods.

For example, in a 2000-liter boiler, the distillation process lasts 3 hours.

The process of obtaining immortelle essential oil is complex and fascinating, requiring expertise and attention to detail at every step. With this detailed insight into distillation, we hope to have brought you closer to the magic behind the production of this precious oil.